CARROUCELL

We care about cells

Benefits

- Optimisation of costs

- Productivity gain X3

- Optimisation of cultivation conditions

- Optimisation of the cellular differentiation

Key words

- Microcarrier

- Cell culture

- Sol-gel

- Microstructuring

Partnerships & Rewards

- 2017 French Deeptech Innovation Competition Winner

- I-Phd 2019 Winner

Linksium Continuum

- Incubation

- Acceleration

Results

- Incorporated startups

Context

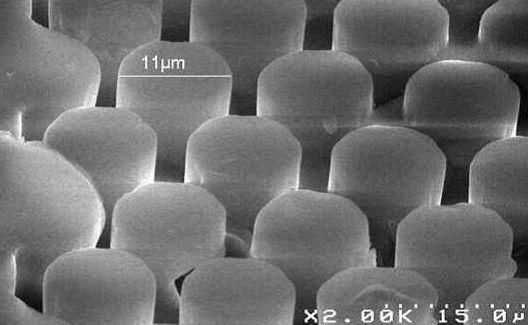

The use of microscopic culture matrices called “microcarriers” has enabled major advances in the field of cell culture. These are tiny balls ranging from a few hundred micrometres to a few millimetres in diameter to which cells can attach themselves and multiply. Unlike other cell culture methods in 2D, 3D mode using microcarriers offers much higher cultivated surface area/volume ratios.

Technology

The glass and ceramics implementing technologies do not allow the structuring of objects sized between a few dozen micrometres and a few hundred micrometres.

Carroucell’s methods makes it possible to obtain sol-gel materials:

- objects with very complex high-precision micro-structures that are impossible to achieve using traditional glass and ceramics implementation methods

- High-purity homogeneous objects (size distribution <3%)

Advantages

Carroucell’s sol-gel process will make it possible to functionalise the microcarriers by giving them special properties (microstructuring of the surface area; biodegradability of the microcarrier by adding other materials, easy integration of interesting molecules, etc.).

State of progress

Industrialisation of the production of microcarriers, cell culture tests of microcarriers.

Partners: EPFL, CTI Biotech

Winning project in the I-Lab competition in the emerging category

Applications

- Improved cell culture yield

- Optimisation of the differentiation of cultivated cells due to the properties of the microcarriers produced using this process