VULKAM

Amorphous metals

Benefits

- Translocator is capable of detecting faults over big distances

- The number of sensors and the cost of the installation are thus reduced

- The accuracy of the detection makes maintenance operations easier

- The choice of communication mode (wireless or by power line) enables the user to adapt to the situation

Key words

- Amorphous metals

- Extreme properties

- Industrial manufacturing

Intellectual Property

- 3 patents

Partnerships & Rewards

- 2017 French Deeptech Innovation Competition Winner

Laboratory

- SIMAP

Institutions

- CNRS

- GRENOBLE INP-UGA

- UGA

Linksium Continuum

- Maturation

- Incubation

- Acceleration

Results

- Incorporated startups

Context

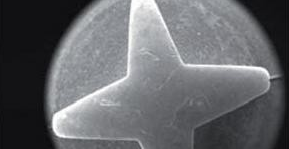

VULKAM's metals are unique. They enable the option to lighten structures, miniaturize systems, limit thermal losses in cryogenics, improve wear resistance... The manufacturing process also opens up new geometries.

Technology

Vulkam industrializes amorphous metals for microtechnics. These metals have an exceptional forming capacity and extreme properties. Vulkam offers a service ranging from the pilot project to the industrial manufacture of finished parts.

Advantages

The future of microtechnology depends on the development of innovative material and process combinations in terms of final properties and parts processability. Amorphous metals are a new class of materials with unique properties, including processability...

State of progress

VULKAM was created in 2017. The company currently employs 10 people and manufactures prototypes for the watchmaking, medical and space industries. Mass production will begin in 2021

Applications

Micro-power transmission, surgical tools, watch mechanisms, dental implants, structural lightening, springs, cryogenic insulation, micromotors, micromechanisms…