MAGNETFAB

Powerful magnets for micro applications

Benefits

- Manufacturing solution for integrated micromagnets

- Magnetic properties equivalent to strongest existing permanent magnets

- As small as a grain of sand

- Key component for higher-performing and more reliable MEMS

Key words

- Integrated micromagnets

- MEMS

- Miniaturization

- Sensors

Intellectual Property

- 1 patent

Partnerships & Rewards

- Fonds FEDER - Région Auvergne Rhône Alpes

- 2025 French Deeptech PhD Competition Winner - Grand Prix

Laboratory

- NEEL

Institutions

- CNRS

- GRENOBLE INP-UGA

- UGA

Linksium Continuum

- Maturation

- Incubation

- Acceleration

Results

- Incorporated startups

Context

Microelectromechanical systems (MEMS) are tiny electronic devices that combine electrical and mechanical components, found in everyday items like smartphones, cars, and medical equipment. They offer benefits like miniaturization and cost reduction. Using powerful rare-earth magnets could allow building higher-performing and more robust MEMS, but current techniques can't produce small enough magnets with the required properties for integration.

Technology

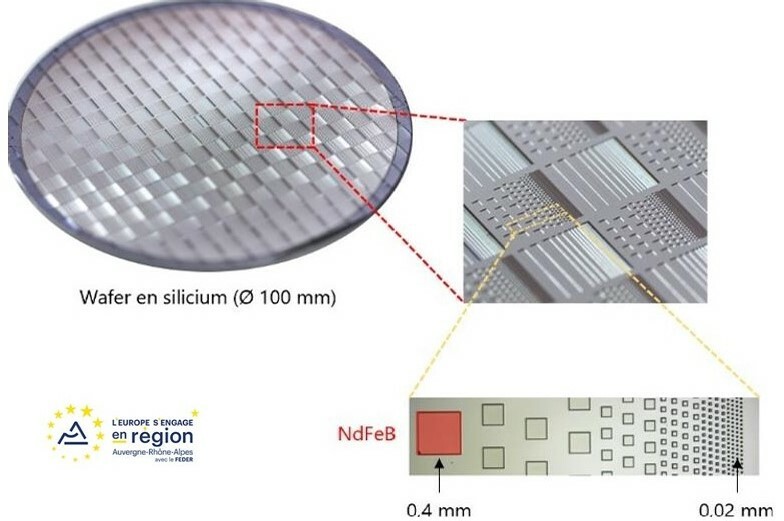

Magnetfab’s innovative solution relies on thin-film deposition by means of high-rate sputtering to fabricate thousands of integrated micromagnets on a single substrate, in an equivalent fashion as integrated circuits and MEMS, and is thereby ideally suited for mass production.

Advantages

These micromagnets are made from a rare-earth alloy with magnetic properties matching the strongest bulk permanent magnets, like those used in most electric car engines. Their sizes and magnetic properties are perfect for MEMS, with highly customizable shapes controlled with micron precision. Variations in magnetic properties between magnets are below 1%. Additionally, this manufacturing method is far more resource-efficient than traditional magnet fabrication techniques.

State of progress

Up to 50 µm thick micromagnets can readily be fabricated on 100 mm silicon wafers. The potential of the micromagnets in MEMS applications has been demonstrated in several proof of concepts, including in a MEMS actuator, a MEMS energy harvester, and in mechanical watch mouvements.

Applications

Miniature loudspeakers, magnetic field sensors, tactile sensors, quantum computer chips, and many more.

Featured articles

SERIAL TECH TRANSFR

SERIAL TECH TRANSFR

1, 2 and 3 startups for Nora Dempsey, National Medal of Innovation 2021

Nora Dempsey is one of the four winners of National Medal for Innovation 2021 awarded by CNRS. Nora Dempsey, born in Ireland, has gained an international recognition for her research in Grenoble on...

Read the article PORTRAIT

PORTRAIT

Amiral Technologies, la startup IA grenobloise spécialisée dans les solutions de maintenance prédictive, intègre Station F

An ambitious promise: to invent a zero-defect and zero-downtime future for industry. Amiral Technologies, a startup co-founded and boosted by Linksium, based on the technological prowess of the Gre...

Read the article