MADCAP-NANO

Microfluidic Advanced Cavitation Processes

Benefits

- Low energy consumption

- Low pressure

- Small installation

Key words

- Anti-corrosion

- Anti-abrasion

- Lubrification

- Graphene

Intellectual Property

- 1 patent

- 1 knowhow

Laboratories

- LEGI

- LGP2

Institutions

- CNRS

- GRENOBLE INP-UGA

- UGA

Linksium Continuum

- Maturation

- Incubation

- Acceleration

Results

- Incorporated startups

Context

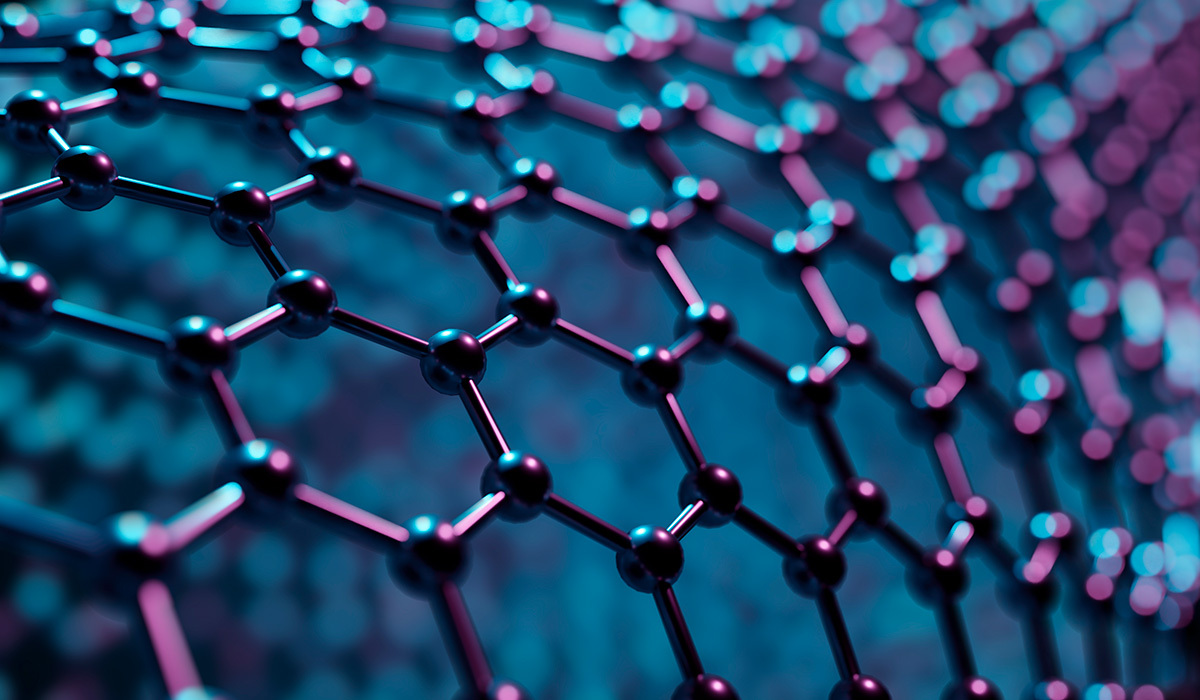

Graphene's exceptional mechanical strength, high specific surface area, extremely low coefficient of friction and biocompatibility make it an obvious choice for the three applications Madcap-nano has selected: additive for anti-corrosion paint, anti-abrasion paint, lubricant deposit or wet lubricant.

Technology

Hydrodynamic cavitation 'on a chip', i.e. cavitation at the heart of fluidic microsystems, has enabled us to develop a new, economical and environmentally-friendly process for exfoliating graphite microparticles into graphene nanosheets dispersed in aqueous solution.

Advantages

This unique low-pressure graphene nanosheet production process consumes very little energy. Madcap-nano will produce graphene-filled solutions in large quantities at prices “finally” compatible with the anti-corrosion, anti-abrasion or lubricant paint markets, for dispersal as additives by coatings formulators.

State of progress

Initial work carried out by LEGI had led to the patenting and validation of a unique micro-fluidic exfoliation process producing nano-leaflets of better quality than those commercially available. Building on this know-how, the Madcap-nano team has joined forces with another Grenoble university laboratory, LGP2, to benefit from its physical chemistry skills in the formulation of complex fluids, in the dispersion of nanomaterials in various liquid or polymeric supports, and in biobased materials such as nanocellulose.

Applications

- Additives for anti-corrosion coatings

- Anti-abrasion surface treatment additives

- Additives for lubricant coatings

- Polymer reinforcement

- Conductive inks for organic electronics