GGG

Grenoble Green Graphenofluids

Benefits

- Low energy consumption

- Low pressure

- Small installation

Key words

- Graphene

- Exfoliation

- Nanosheets

- Single layer

Intellectual Property

- 1 patent

- 1 knowhow

Laboratory

- LEGI

Institutions

- CNRS

- GRENOBLE INP-UGA

- UGA

Linksium Continuum

- Maturation

- Commercialization

Results

- Available licenses

Context

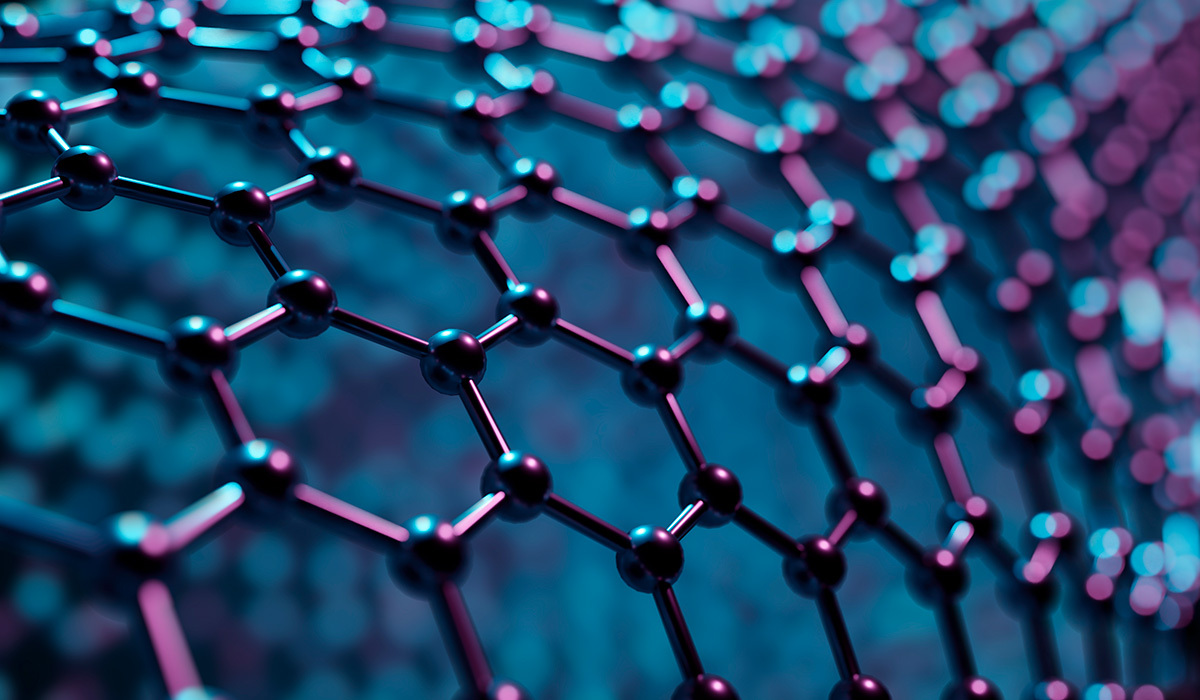

In the context of Graphene being the material of the future due to its particular properties in strength, thermal and electric conductivity, transparency, etc..., research conducted at the LEGI Grenoble has resulted in an innovative liquid exfoliation process.

Technology

The graphene nanosheets are exfoliated from graphite particles by an innovative microfluidic process using hydrodynamic cavitation ‘on a chip’. The production process is working at low pressure and low energy consumption. The produced graphenofluid is a suspension of graphene nanoplatelets.

Advantages

The centrifuged solution contains single layer and bilayer graphene. High stability of the dispersions has been proven for over 6 months.

- Concentration 1.50 g/L

- Thickness < 5 nm

- Lateral size ≃ 150-200 nm

All results are confirmed by qualitative and quantitative measurements.

State of progress

A first prototype of the microfluidic system has been set-up in the laboratory in 2018. The realization of a five-channel parallel installation allowed the development of a production capacity of 5.5 g per week.

With low power consumption, it exfoliates very small graphene nanosheets in an aqueous solution. Initial application tests on lubrication have shown a 20% reduction in wear and tear. Other tests are in progress or to come.

Applications

- Cooling systems

- Lubrification

- Water treatment

- Polymer chemistry

- Paints and coatings

- Conductive inks