GAMMA TECH

Using sol-gel technology to manufacture 3D objects

Benefits

- Integration of mineral or organic nanoparticles

- Low-carbon footprint process

Key words

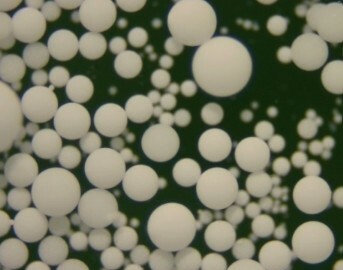

- Mesoporous and functionalized microspheres

Intellectual Property

- 2 patents

- 1 knowhow

Partnerships & Rewards

- Région Auvergne-Rhône-Alpes

- 2021 i-PhD French Deeptech PhD Competition Winner

Laboratory

- LRP

Institutions

- CNRS

- GRENOBLE INP-UGA

- UGA

Linksium Continuum

- Maturation

- Incubation

- Acceleration

Results

- Incorporated startups

Context

The field of advanced materials is faced with a number of challenges: a high level of performance, competitiveness, production and supply capacity in Europe. Recently, ‘sustainable development’ has become part of the materials selection criteria. GAMMA Tech is fully in line with this trend, using chemistry rather than an energy-intensive glassmaking process to manufacture customized silica microspheres. |

Technology

GAMMA Tech uses sol-gel technology (soft chemistry). Production takes place at room temperature, which means that nanometric-sized organic or inorganic additives can be incorporated. This is not compatible with the conventional glass melting process. The fillers created by the sol-gel process are therefore multifunctional and have a low carbon impact. |

Advantages

GAMMA Tech is positioned to offer specific microspheres to replace critical materials (TiO2 in paint) or comply with REACH regulations on microplastics (polymers, coatings) or nanoparticles (cosmetics). GAMMA Tech helps potential customers to comply with their CSR strategies.

State of progress

With the lab atomiser in operation, the first samples of solid and mesoporous microspheres (TRL 6) can be delivered in quantities of a hundred grams. R&D is focusing on hollow microspheres and work on properties such as specific surface area or the integration of specific pigments. The next round of funding will enable us to acquire greater production capacity to serve our first customers.

Applications

GAMMA Tech is targeting paint, coatings and cosmetics manufacturers to conduct POCs in Europe. In addition to lightening the weight of matrices, GAMMA Tech's microspheres can be used to improve optical properties, provide mechanical reinforcement or even sorption/desorption capacities, or act as supports for catalysis or gas filtration by varying their specific surface area.