MOTRHYS

MOnitoring of TRansients for HYdro Safety

Benefits

- Hydraulic expertise with the operators

- Pressure monitoring of penstocks

- Automation of hydraulic diagnosic

- Data treatment

Key words

- Signal processing

- Hydraulic expertise

Intellectual Property

- 2 software

Partnerships & Rewards

- 2018 French Deeptech Innovation Competition Winner

Laboratory

- GIPSA-LAB

Institutions

- CNRS

- GRENOBLE INP-UGA

- UGA

Linksium Continuum

- Maturation

- Incubation

Results

- Incorporated startups

Context

With the emergence of renewable energies, hydropower is increasingly used as backup energy and as a mean of storing energy. Pumped storage plants provide 95% of electricity storage requirements, while storage dams, with their capacity to start & stop quickly allow electricity needs to be adjusted in real time (Smart Grid networks and system services).

These shutdowns/starts are generating huge constraints on the structure of the hydropower plants and more specifically on the penstocks, it is necessary monitor and control in real-time these constraints to ensure the security of the power plant.

Technology

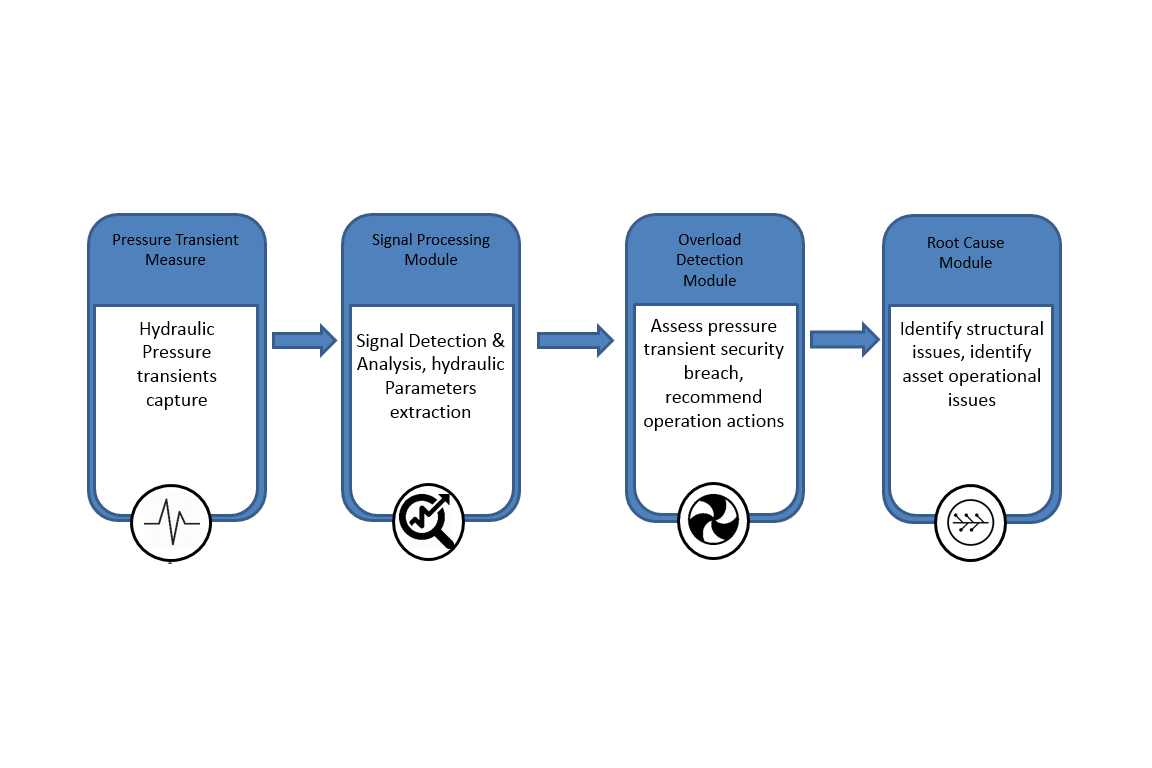

From the pressure tap at the bottom of the penstock each new transient pressure signal is processed by the SPM (Signal Processing Module), key physical parameters for the hydraulic diagnosis are extracted from the signal. The physical parameters are then sent to the Overload Detection Module (ODM), which elaborates the multi-parameter defect descriptors: propagation lengths of the extreme values of the pressure along the pipe, damping or self-sustainability of the pressure oscillations, risks of cavitation…

The comparison with the eligibility thresholds (maximum permissible pressure of each section and component, cavitation pressure level, damping time) makes it possible to detect the presence of defects but also to estimate their severity (hydraulic diagnosis).

The Root Cause Module (RCM) synthesizes the data from the ODM: the comparison with the characteristics of the pipe and the specificities of the components and machines associated with the penstock makes it possible to confirm the diagnosis by refocusing on the monitored installation.

Advantages

Ease of deployment (1 point of measurement per penstock).

Real time & continuous monitoringquick & reliable diagnosis

Enabling predictive maintenance

State of progress

The initial version of the product is available.Motrhys has established a partnership with Yokogawa who provides the instrumentation part of the solution (pressure transient recorders). Motrhys is a graduate of the iLAB French Innovation Contest in 2018.

Applications

MOTRHYS' software solutions improve the safety of penstocks by continuously analysing the pressure transients, and its associated overload risk, related to dysfunction or turbo machines malfunctions and associated circuits: starts, stops, leaflets manoeuvres, resonances and instabilities. Motrhys’s HydroSurge solution allows operators of hydro-power plants to perform predictive maintenance while minimizing the downtime of operation and maximizing the security ensuring optimized operation of the plant.